- PRODUCTS

-

UP.SIGHT™ NEW

Optimized For Proof Of Monoclonality, Colony Tracking, Confluency, & Titer Measurement -

F.SIGHT™ 2.0

Optimized For Rapid Dispensing of Fluorescent Cells -

C.SIGHT™ 2.0

Optimized for Powerful Dispensing of Unlabeled Cells -

B.SIGHT™

Optimized For Rapid Microbial Single-Cell Isolation and Cultivation -

F.SIGHT™ OMICS

Optimized For Single-Cell-Omics -

F.SIGHT™

Optimized For Affordability And Flexibility -

C.SIGHT™

Optimized for Affordable Cell Line Development - Help Me Choose

-

UP.SIGHT™ NEW

- APPLICATIONS

- RESOURCES HUB

- COMPANY

- SHOP

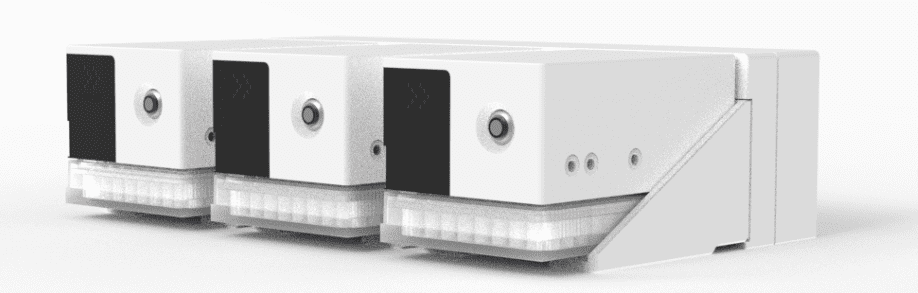

S.NEST™

The high-throughput microbioreactor with CO² incubation capabilities to optimize your cell

line development.

Join 1,000+ Biopharmaceutical Companies and Academic Institutions

Key Features & Benefits

Find out how our product can enrich your research

More control over experiments

Customize the mixing level and increase cell growth with the S.NEST’s unique fluid control system

Maximum productivity

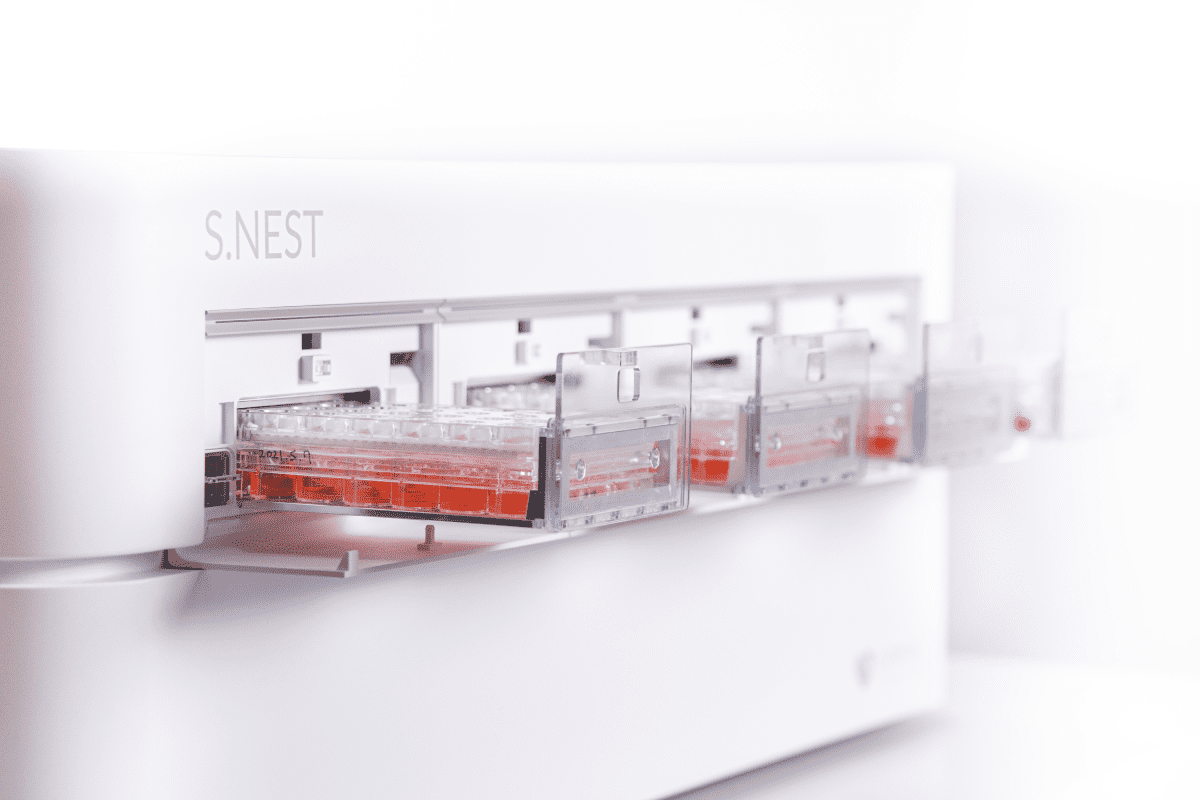

Incubate up to four 24- or 96-well plates at once for maximum productivity and efficiency

Real-time

monitoring

Optical sensors at the bottom of the unit monitor pH and dissolved oxygen (DO) values through the entire cell culture process

Efficient interpretation

Valuable insights of pH/DO data throughout the culture period enable high throughput cell clone selection

Faster

processing

Reduce the amount of time required to process cells

Better

results

Cells show higher density and viability when processed in the S.NEST compared to traditional incubation

Product Details

Discover what you can do

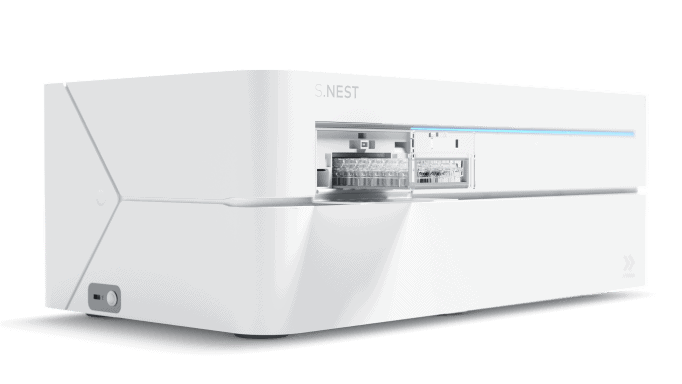

Increased oxygen transfer

The S.NEST exerts suction or expulsion pressure through the fluidic channels to enable homogenous reciprocating mixing. The oxygen transfer tubes connected to the lid offer the cells a continuous oxygen supply to maintain a healthy environment.

Consumables for

optimal cell culture

optimal cell culture

The S.NEST lid comes in 96-fluidic-channel or 24-fluidic-channel formats for respective well plates. The patented condenser design in the fluidic channels effectively reduces liquid evaporation, and condensation collected at the surface of the condenser circulates back into the culture during every mixing.

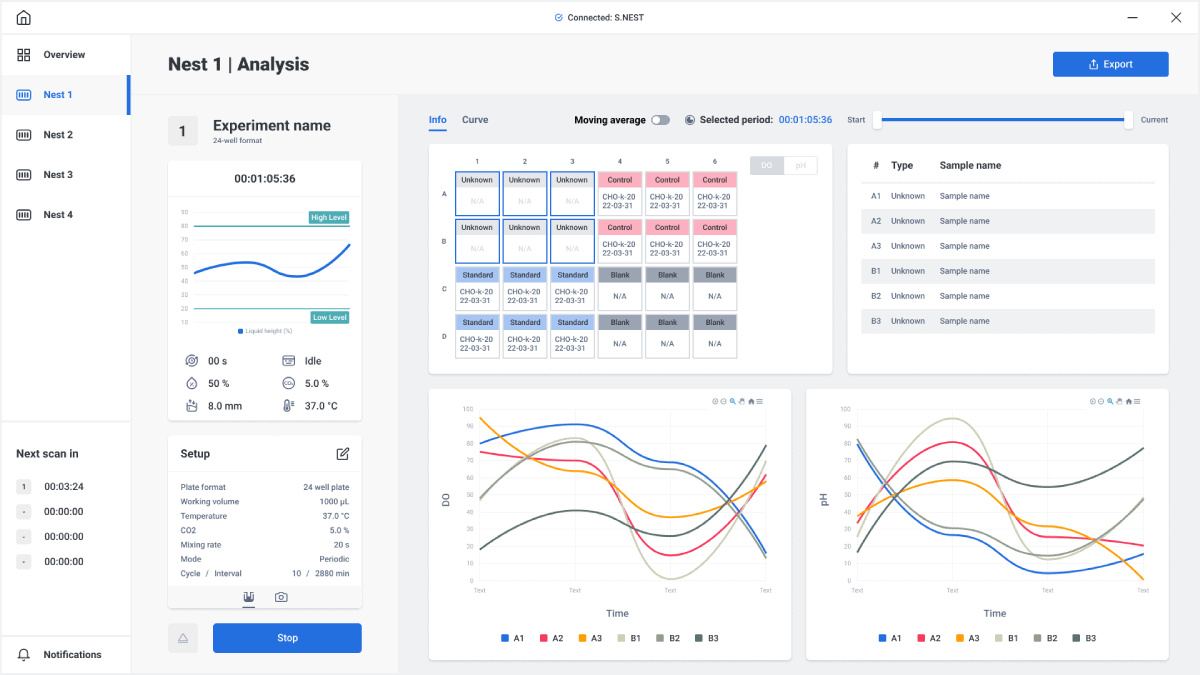

Software

The S.NEST provides insightful graphs from pH and DO sensor data, including measurements and a heatmap from each well through the duration of your experiment. The software also provides intuitive settings for the incubation chamber environment, mixing system and motion camera.

Real-time monitoring

The S.NEST provides sensor results in real time and allows users to adjust

environmental controls.

Designed for your needs

The S.NEST consists of an upper and lower section. The upper part includes the four incubation chambers that each include a thermal module, water tray and air/CO2 inlet port and sensor. The lower section is a motion camera module that detects the optical signals from the sensors within 5 minutes and displays real-time data from taken from each plate on the

system’s software.

Product

Applications

Accelerate your research

Cell line development (CLD)

High-throughput clone selection

Cell culture upscaling

Immunology

Transfection efficiency

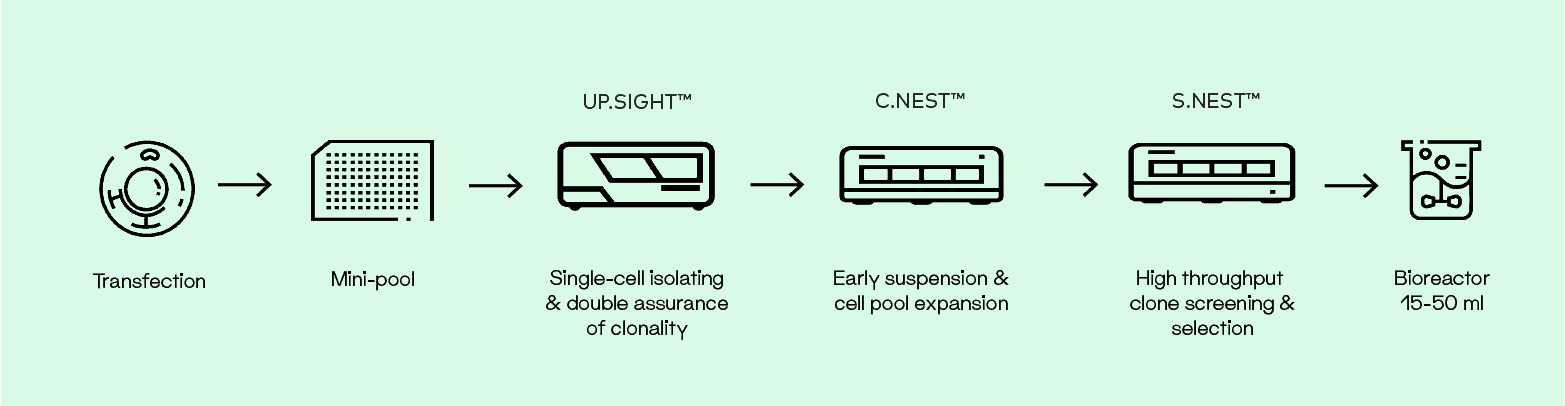

Featured Workflow

Combined with one of our single-cell dispensers like the UP.SIGHT™, the S.NEST™ can help

laboratories save up to 13 weeks of processing time.

Download Application Notes

For scientists by scientists, these notes highlight novel ways to optimize

your research with our products and solutions

your research with our products and solutions

No Posts Found.

Product Datasheet

| Working volume (24-well format) | 1000 – 1600 μL |

| Mixing rate (24-well format) | 10 – 50 seconds (± 5 %) |

| Temperature control | RT+5 – 45 °C (± 0.2 °C) |

| CO2 level control | 1 – 20% (± 0.3%) |

| Humidity monitoring (at 37°C) | 0 – 100% (± 5 %) |

| DO measurement | 0 – 100% (± 5 %) |

| pH measurement | 6.0 – 8.0 (±0.2) |

| Sampling rate | ≥ 10 min |

| Footprint (WxDxH) | 785 x 434 x 288 mm |

| Weight | 43 kg |

| Input voltage | 100-240 VAC |

| Input current | 1.45-3.53 A |

| Input fuse type | 250 VAC, 16A |

Starting from $115,000