- PRODUCTS

-

UP.SIGHT™ 2nd GenNEW

Optimized For Proof Of Monoclonality, Colony Tracking, Confluency, & Titer Measurement -

F.SIGHT™ 2.0

Optimized For Rapid Dispensing of Fluorescent Cells -

C.SIGHT™ 2.0

Optimized for Powerful Dispensing of Unlabeled Cells -

B.SIGHT™

Optimized For Rapid Microbial Single-Cell Isolation and Cultivation -

F.SIGHT™ OMICS

Optimized For Single-Cell-Omics -

F.SIGHT™

Optimized For Affordability And Flexibility -

C.SIGHT™

Optimized for Affordable Cell Line Development -

Compare Products

Decide which one is right for you - Help Me Choose

-

UP.SIGHT™ 2nd GenNEW

- APPLICATIONS

- RESOURCES HUB

- COMPANY

- SHOP

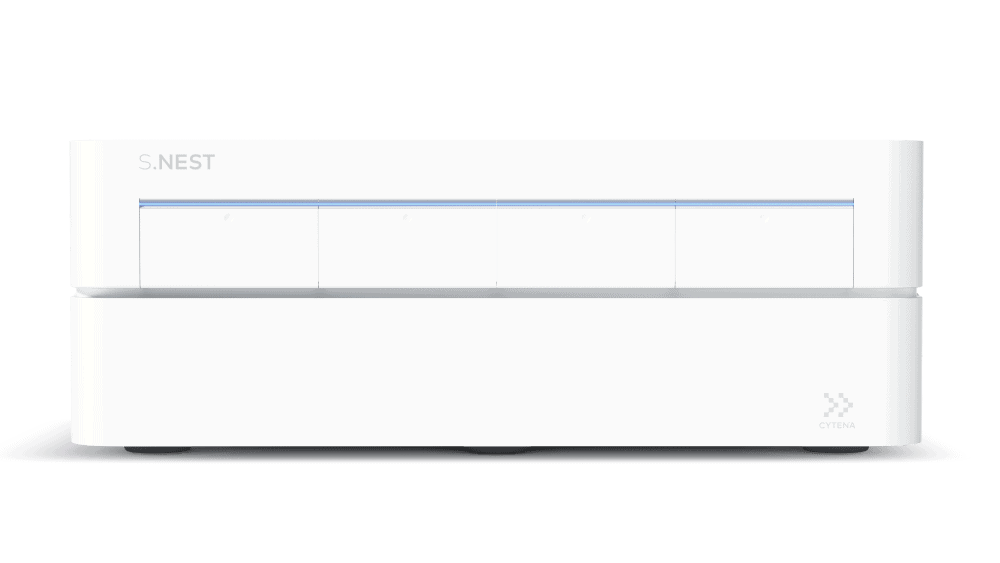

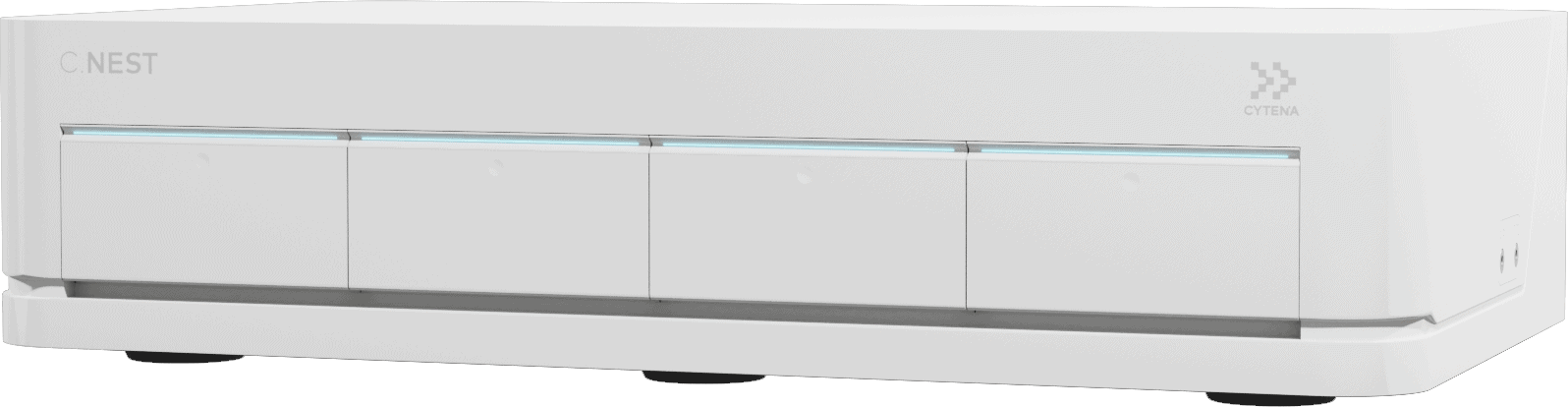

Microbioreactors

Our award-winning microbioreactor systems are equipped with innovative technologies and patented components that are able to revolutionize cell culture. It’s intuitive, easy to use and compatibly used with 96-well and 24-well plates. Whether it is cell line development, biologics production, or drug screening, our microbioreactors can help to offer a much healthier culture environment, shorten the process time and eventually, find the best clones faster.

Why Our Microbioreactors?

Productivity

The high-throughput fashion

enhances productivity and

efficiency in workflows

Flexibility

Optimized and up-scalable

systems that offer

personalized experience

Reliability

Precise control system with

optimal conditions for cell growth

and viability

Versatility

Supporting a wide range of

application areas

Intelligence

Controlled by software with

intuitive interface &

intelligent design

Advancing Discovery

Find better clones faster

Who

Is It For ?

Biopharmaceutical

Industry

Academic

Institutions

Life Sciences

Startups

Government

Research Facilities

CRO/CDMO

Biopharmaceutical

Industry

Life Sciences

Startups

CRO/CDMO

Academic

Institutions

Government

Research Facilities

Featured

Applications

Cell line development

High yield protein production

Virus production

Spheroid, organoid

& 3D culture

Stem cell & Cell therapy

Featured Resources

Discover more about our single cell dispensers and what you can do with them.

Applications

Learn how you can automate research workflows in numerous application areas