- PRODUCTS

-

UP.SIGHT™ 2nd GenNEW

Optimized For Proof Of Monoclonality, Colony Tracking, Confluency, & Titer Measurement -

F.SIGHT™ 2.0

Optimized For Rapid Dispensing of Fluorescent Cells -

C.SIGHT™ 2.0

Optimized for Powerful Dispensing of Unlabeled Cells -

B.SIGHT™

Optimized For Rapid Microbial Single-Cell Isolation and Cultivation -

F.SIGHT™ OMICS

Optimized For Single-Cell-Omics -

F.SIGHT™

Optimized For Affordability And Flexibility -

C.SIGHT™

Optimized for Affordable Cell Line Development -

Compare Products

Decide which one is right for you - Help Me Choose

-

UP.SIGHT™ 2nd GenNEW

- APPLICATIONS

- RESOURCES HUB

- COMPANY

- SHOP

ELISA

Automate and optimize your ELISAs for faster

and more efficient screening.

and more efficient screening.

Overview

Enzyme-linked Immunosorbent Assays (ELISAs) are a common analytical methodology used to quantify antigen concentrations in any given solution. Thanks to the straightforward nature of the method, ELISAs have been used for a variety of applications ranging from HIV diagnosis and pregnancy tests to more delicate antibody, antigen and protein measurement.

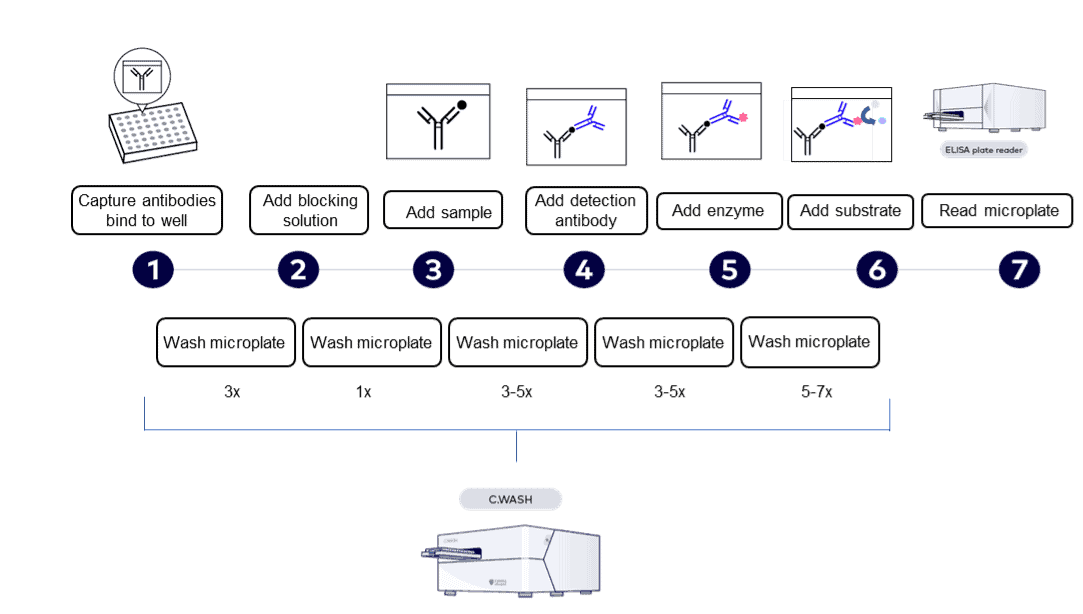

Detection of specific targets is based on the binding of specific antibodies, immobilized on a solid phase. An enzymatic reaction from those antibodies produces a measurable readout, which can then be used to quantify a target protein in the solution. To generate high-quality data for evaluation, it is of utmost importance to ensure that non-specific bound proteins or antibodies causing background noise are removed.

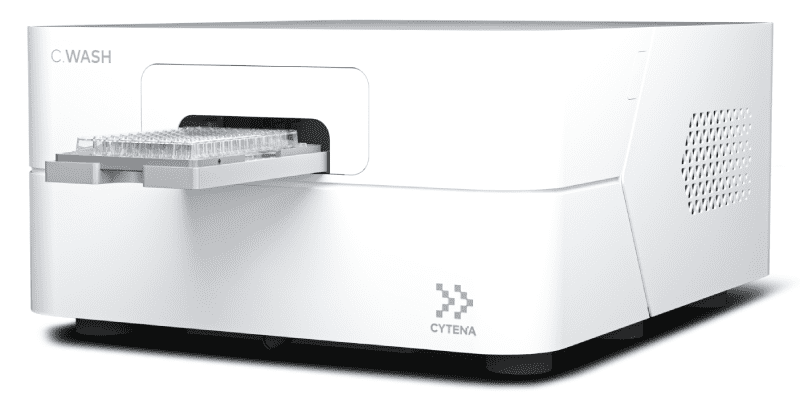

Typically, ELISA protocols contain multiple wash cycles after each reaction step to reduce interference from background noise. CYTENA’s automated plate washing and liquid handling system, the C.WASH, reduces the time and resources typically needed in this process by using centrifugal force to clean microplates. In addition to accelerating the process, the C.WASH

Sub-Applications

Accelerate workflows

Remove liquids from 96-, 384- and 1536-well plates in seconds without the use of plastic pipette tips.

Automation

ready

Futureproof your workflows with an automation-ready device (SILA2).

Minimize cross

contamination

Noncontact liquid removal reduces the chance that samples will mix with contaminants, assuring that data generated during tests is accurate and reliable.

Research Workflows

Simplify washing steps

The workflow below outlines how the C.WASH can be integrated into a sandwich ELISA workflow, from the initial antibody binding steps to the final enzyme and substrate addition. As mentioned previously, ELISAs have washing steps after each addition of sample and/or binding agents. The C.WASH aims to simplify these washing steps by using centrifugal forces for noncontact liquid removal, which effectively washes plates in as few as two cycles.

Featured Resources

Previous

Next