Automating Cell Line Development

with C.STATION Powered by GBG

Thursday, November 30

11:00 AM - 12:00 PM EST

Virtual

Trusted By 1000s Of Your Peers At Premier Research Labs Worldwide

This does not happen by accident.

Learn about

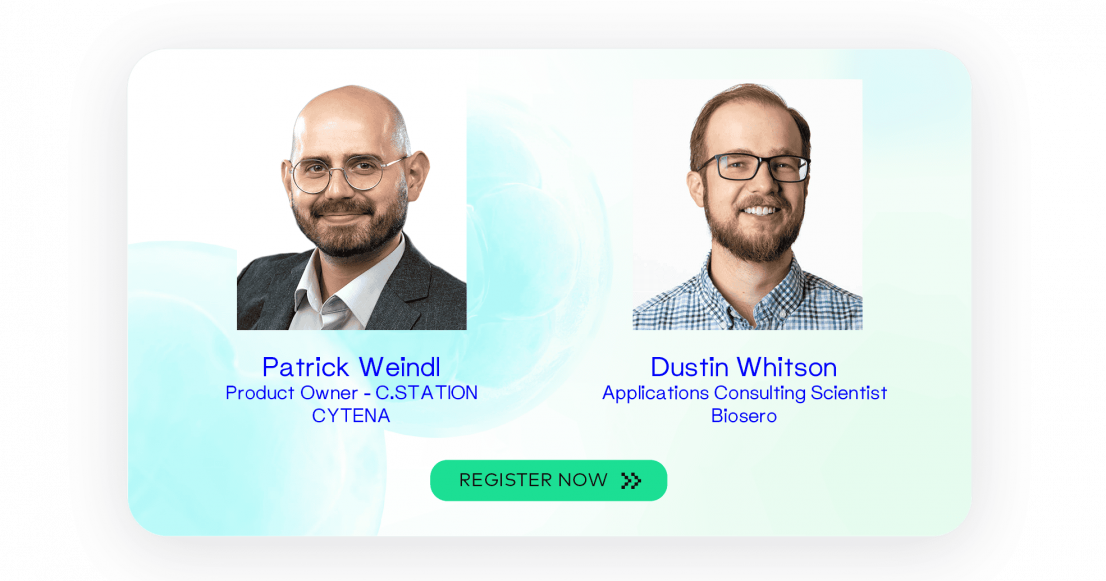

our speakers

Patrick Weindl holds a degree in Biotechnology and has a keen interest in the integration of cutting-edge technologies within laboratory settings. With extensive experience in benchtop device development, he has honed his skills in hardware design, embedded electronics, and semi-automated software, particularly in the sectors of aerosol toxicology and pharmaceuticals. In early 2022, Patrick joined CYTENA as the Product Owner of the C.STATION. In this role, he is responsible for overseeing the technical implementation of hardware, ranging from robotics to sterility measures, as well as leading the development of a comprehensive software suite. This suite enables CLD scientists to concentrate on core research activities, alleviating the burden of routine tasks.

Dustin Whitson is an Applications Consulting Scientist at Biosero where he works with scientists from labs around the world to design solutions for automating science. With 8 years of experience as a bench scientist in both research and forensic labs, Dustin understands firsthand what labs need from their automation solutions. He has spent the last 6 years specializing in delivering automation into the lab setting with applications experience at Biosero and Hamilton Robotics.

Peerless: In Quality and

Customer Support

Global

Market Leader

Pioneers of the single-cell dispensing category

Made

in Germany

Engineered with Uncompromising Quality

Onsite Service

& Support

Europe, UK, USA, Singapore, South Korea and Japan

World

Class Expertise

Years of History of Success and Growth

FAQ

- All C.STATIONs: up to 28 mm plate height, e.g. 384/96/48/24/12/6-Well plates

- With fed-batch option: up to 47 mm plate height, e.g. 96/48/24/12/6-Deepwell plates

The C.STATION is molecule-agnostic to a large extent. The workflows can be freely configured to fit the specific needs of each development campaign. Our customers use the C.STATION for development of different types of molecules. CYTENA typically validates and develops features employing mAB-producing cell lines.

Manual interventions are limited to planning and initiating campaigns, as well as supplying consumables such as cartridges for single-cell dispensing, racks with pipette tips, reagents, and empty well plates.

No, the C.STATION program does not require in-house expertise, as it is tailored to allow operators to focus on their application, workflow, and results. By design, the software on the C.STATION offers numerous options for parametrization, including aspects such as schedules, workflows, liquid handling, imaging, and dispensing.

No, however, Green Button Go simplifies the process of automating a range of liquid handlers within a customized work cell. For more information, please contact Biosero.